|

INDY PRO SERIES CAR SPECIFICATIONS

(Courtesy of IndyPro Series):

ENGINE PROGRAM:

Manufacturer: Infiniti

Capacity: 3.5 Liters

Configuration: 90-degree V8

Horsepower: 450 @ 8,200 RPM

Infiniti is the

sole engine manufacturer of the Indy Pro SeriesT. The series

uses a 3.5-liter racing version of the engine found in the

Infiniti Q45 luxury performance sedan.

The Infiniti Q45

has always focused on performance in the highly-competitive

premium luxury class, and one of its outstanding

characteristics is its powerful 4.5-liter, V8 engine that

produces up to 340 horsepower. The Q45 represents the pinnacle

of Infiniti's performance technology. The fact that the Indy

Pro Series selected this production engine to power its racing

series is one of the best accolades one could receive. It is a

testament to the Infiniti brand that the Menards Infiniti Pro

Series can take its production parts to use on the race cars

under extreme racing conditions at speeds in excess of 180

mph.

As Infiniti enters

its 16th model year for 2005, the expanded lineup includes the

QX56 full-size luxury SUV, Q45 performance luxury sedan,

all-new M45 performance sport sedan, FX35 and FX45 premium

crossover SUVs, G35 Sport Coupe and Sport Sedan,. This lineup

has earned praise for its advanced technology, leading-edge

safety features, lightweight and aerodynamic body designs,

innovative styling and attention to comfort and luxury. A

network of over 160 dealers in the United States supports

Infiniti, the luxury division of Nissan North America, Inc.

CHASSIS PROGRAM:

|

Chassis Regulations |

|

Type:

|

Open-wheel,

single-seat, open-cockpit and ground-effect underbody;

outboard wings front and rear |

|

Construction: |

Monocoque

contains cockpit, fuel cell and front suspension; engine

is stressed (integral) member of chassis; rear assembly

contains gearbox and rear suspension members |

|

Materials: |

Carbon

fiber and composites |

|

Weight: |

1,430 pounds

minimum, including all lubricants and coolants used during

the event, but does not include fuel or driver

|

|

Length: |

191.5

inches minimum |

|

Width:

|

75 inches,

plus or minus 1/2 inch. |

|

Wheelbase: |

117

inches. |

|

Wheel

Size: |

15-inch

diameter x 10 front; 15-inch diameter x 14 rear.

|

|

Tires: |

Firestone

Firehawk |

|

Gearbox: |

Ricardo Six

forward gears, sequential shifter |

|

Fuel Cell: |

Single,

rupture-proof cell, 25 U.S. gallons (standard)

|

|

Cost: |

$115,000

(including data acquisition system) |

|

Manufacturers: |

Dallara

Automobili, Italy |

TIRE PROGRAM:

Nashville-based Bridgestone/Firestone North American Tire, LLC is a subsidiary of Bridgestone/Firestone Americas Holding, Inc., whose parent company, Bridgestone Corporation, is the world's largest tire and rubber company. BFNT develops, manufactures and markets Bridgestone, Firestone, Dayton and associate and private brand tires. The company is focused on wholesale and original equipment markets, supplying passenger, light truck, commercial vehicle, off-road, agriculture and other tires to its customers in North America.

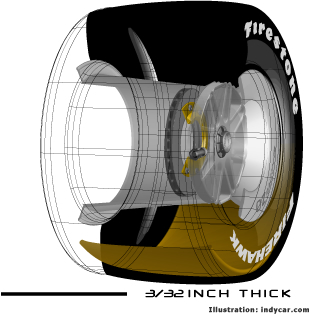

Fortunately, Indy Pro Series cars don't have to run in the snow.

Aside from lacking a heater, their tires wouldn't measure up to the

slick roads.

Follow these simple directions to get a look at Firestone tire tread

depth:

Step A:

Remove credit card from wallet/purse.

Step B:

Examine thickness of card.

Step C:

Note that tire tread depth on Indy Pro Series cars is about as thick

as the card (3/32nds of an

inch).

Step D:

Be

thankful your passenger car tires have more trend depth.

Fast facts about tires on Indy Pro Series cars:

-- Are 15 inches in diameter.

-- Are 10 inches wide and weigh about 30 pounds on the front and 14

inches and weigh about 30 pounds on the rear.

-- At any given moment during a race, the total area of all four

tires that is in contact with the track is equal to about one square

foot (about the size of a sheet of notebook paper).

-- At speed, tread area approaches the temperature of boiling water

(212 degrees Fahrenheit). The tread actually becomes tar-like in

consistency.

-- Are inflated with filtered air or nitrogen to remove moisture and

computer balanced.

-- Ambient temperature can have an impact on tires.

Rules of the road

Indy Pro Series teams must pay attention to the number of tires at

their disposal on race weekends.

The three sets Firestone tires provided to teams are aligned with

race distances. Teams must take into account that the fixed number

is for practice, qualifying and the race.

|

Street Tire |

Race Tire |

|

Width:

Weight:

Lifetime:

Tread pattern:

Tread Thickness:

Rubber footprint |

Approx. 8 inches

33 pounds

Up to 80,000 miles

Various

Under 1/2 inch

Significant amount of void due to tread pattern |

Width:

Weight:

Lifetime:

Tread pattern:

Tread Thickness:

Rubber footprint |

14 inches

22 pounds

100 miles

None

3/32 inch

100% contact |

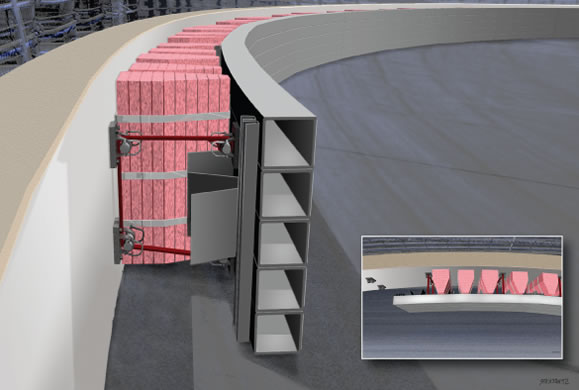

SAFER BARRIER:

Under development by the IRL and the University of

Nebraska-Lincoln's Midwest Roadside Safety Facility since 1998, the

SAFER Barrier was designed to reduce the level of impacts by IRL

cars.

The SAFER Barrier is constructed in 20-foot modules, with each

module consisting of four rectangular steel tubes, welded together,

to form a unified element. The modules are connected with four

internal steel splices. Bundles of 2-inch-thick sheets of extruded,

closed-cell polystyrene are placed between the concrete wall and the

steel tubing modules.

In addition to the Indianapolis Motor Speedway, more than 25 tracks

which play host to auto racing events have installed the SAFER

Barrier. As of January 2005, 11 of the 14 oval tracks on the IRL

schedule had installed the system in all four turns.

Speedway and IRL officials, working with NASCAR and the Midwest

Roadside Safety Facility, continue to try to improve the barrier

through test crashes at the Midwest Roadside Safety Facility in

Nebraska and analysis of all crash data. Every time the SAFER is

impacted, the developers look at the results, driver injuries,

damage to the car, and damage to the SAFER system to determine if

any modification could be made to improve those results.

Since its introduction, the SAFER Barrier has earned four major

awards that has been presented to honor Tony George and the SAFER

Barrier development team.

TIMING AND SCORING:

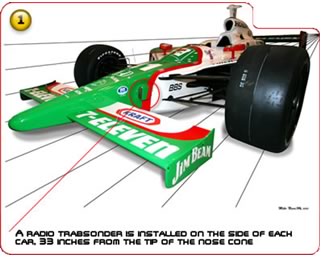

1. A radio transponder is installed on the side of each car, 33

inches from the tip of the nose cone.

2.

Multiple cables buried beneath the track record each car's passing

and transmit the data via a trackside decoder to the timing and

scoring booth. The information is

then fed to the TAG Heuer timing and scoring stand located in the

pit lane at the start/finish line is a camera which takes a picture

every ten-thousandth of a

second. The camera played a vital role in

determining the race winner at Kansas in 2004 when Buddy Rice edged Vitor Meira by .0051 of a second (below). second. The camera played a vital role in

determining the race winner at Kansas in 2004 when Buddy Rice edged Vitor Meira by .0051 of a second (below).

3.

The information is assimilated and sent out to various entities,

including all race teams, which are hard-wired into a network

running along pit lane. The teams receive a general timing and

scoring report showing lap times and speed, as well as a

more-detailed data feed of passing and section data which allows for

real-time analysis.

.

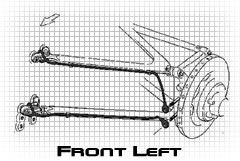

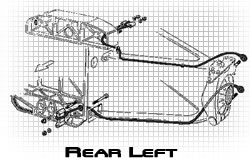

SUSPENSION & WHEEL ENERGY

MANAGEMENT SYSTEM (SWEMS):

The

Suspension

& Wheel

Energy

Management

System has

been required on every car since the 83rd Indianapolis 500. The

SWEMS principle utilizes multiple restraints attached at multiple

points to a car's chassis and suspension to minimize the

possibilities of wheel assemblies becoming detached during

high-speed accidents. The SWEMS was applied to rear-wing assembly in

2001.

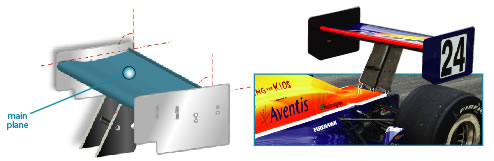

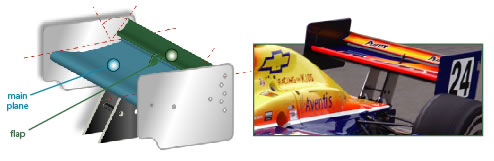

WING CONFIGURATIONS:

During the 2006 season, Indy Pro Series teams will employ two

rear-wing configurations. The rear-wing package varies according to

track.

Superspeedway Wing

Short Track, Road & Street Course Wing

Consists of the standard mainplane with a top flap. The IRL-designated

minimum flap angle varies according to track. The two-element wing

increases downforce and drag and limits speeds.

SAFER INNOVATIONS:

2003:

All cars are equipped with a device that measures and communicates

the impact of a crash to rescue and safety workers on the scene.

Controlled by Delphi's Accident Data Recorder, a light illuminates

when a crash reaches or exceeds a pre-set threshold, informing

safety workers that an injury is more likely.

2002: The

SAFER (Steel and Foam Energy Reduction) Barrier is installed in all

four corners of the Indianapolis Motor Speedway prior to the

beginning of practice for the 86th Indianapolis 500. Under

development by the Indy Racing League and the University of

Nebraska-Lincoln's Midwest Roadside Safety Facility since 1998, the

SAFER barrier is designed to reduce the severity of impacts by Indy

Racing League cars.

2000:

Collapsible steering columns are introduced.

2000:

Delphi Accident Data Recorders are installed in all IndyCar Series

cars.

1999: The

Suspension & Wheel Energy Management System is required on every car

for the 83rd Indianapolis 500. The SWEMS principle utilizes multiple

restraints attached at multiple points to a car's chassis and

suspension to minimize the possibilities of wheel assemblies

becoming detached during high-speed accidents. The SWEMS was applied

to rear-wing assembly in 2001.

1998:

Attenuators are added to the rear of the Indy Racing League

gearboxes to lessen g-forces in rear-impact crashes.

1998: Indy

Racing League technical staff and Delphi Automotive Systems

engineers develop a yellowlight warning system. When a caution is

called on the track, a yellow light blinks in the cockpit, providing

the driver with immediate notifi cation of the caution. The system

is fi rst used at the 82nd Indianapolis 500.

|